For more than 60 years the aluminum association has worked with the industry to develop and maintain technical standards for aluminum production.

Aluminum sheet flatness tolerance.

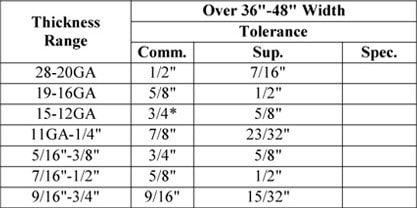

Only short span flatness tolerance applies short span flatness 5 tolerance 6 in.

The measurement being from the highest point or points of the sheet or plate to the table surface minus the material thick ness.

0 125 to 0 374 0 0015 aluminum.

Aluminum plate tolerances xlsx author.

This alloy plate has a standard aluminum association tolerance of 1 for a thickness range from 0 25 to 0 624 and a tolerance of 075 for a thickness range of 0 625 to 8.

Back to login send one time password.

These flatness guarantees are both before and after machining.

The k100 s plate is ideal for machine work requiring vacuum integrity.

Ams and astm standards exist which cover the flatness requirements for most plate and sheet items as produced by the mill.

From designating alloys to answering technical questions to engaging with the academic community the association s standards technology department creates the backbone of a vital communication.

The flatness tolerance for k100 s material between 250 and 500 thickness is within 015 while the flatness tolerance for material between 625 and 8 00 thickness is within 010.

A ruler which does not flatten the material will give the degree of flatness.

Allowable deviation from flat tx51 tempers 2 aluminum technical data sheet and plate flatness tolerances flatness tolerances flat sheet 1 alloy includes alclads specified thickness in.

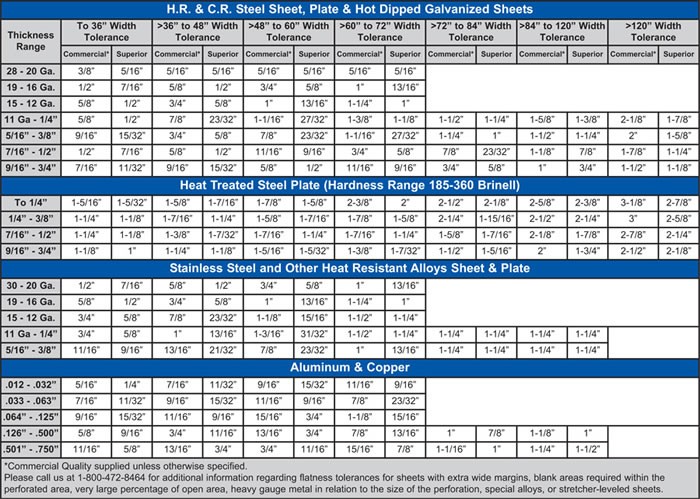

The requirements on the flatness of the plate and sheet products sold by rolled alloys vary considerably by the type of product by alloy by thickness and by the size of the piece.

Estimate lbs plate estimate plates per skid exact.

Fill in your e mail and we will send you a one time password you can use to login with.

Aluminium plate flatness tolerances to download the aluminium plate flatness tolerances document please click on the link or the image below.

Please complete the enquiry form located on this page call 44 0 330 223 2653 or email us to discover how we could be supplying you with premium metal products and professional metal processing services.

2011 t3 2024 t4 6061 t6 t651 cold finish.

Once logged in you can change your password if you wish.