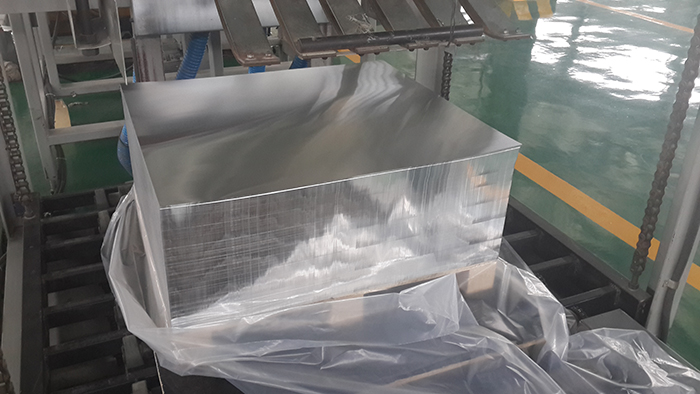

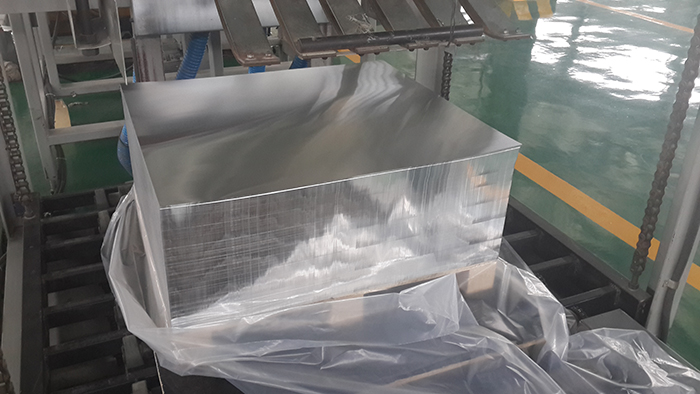

Aluminum composite navard aluminum mfg.

Aluminum clad brazing sheet.

6061 6062 6063.

As an alternative one side can be clad with a non braze alloy e g.

Low density core inserted in between two relatively thin skin layers.

Some of our clients.

Aluminum brazing sheet for brazed automobile heat exchangers cladding an aluminum silicon alloy with a brazing sheet provides an aluminum alloy that has the thin walls necessary for use in automobile heat exchangers as well as such desirable characteristics as high strength corrosion resistance and formability.

Brazing sheet is a composite material typically consisting of a core alloy and one or more liner alloy that are metallurgically bonded clad to the core alloy.

Contact lynch metals inc.

I structure of multiclad key words vacuum brazing clad aluminum aa 4004 cladding aa 3003 6063 core multilayer cladding silicon diffusion diffusion from clad diffusion into core clow discharge optical spectroscopy has a core of an alloy from the aa 3000 series.

Brazing sheet comprises of a core alloy clad on 1 or 2 sides with a lower melting aluminum silicon al si alloy.

Main application for aluminum brazing sheet.

It melts and flows during the brazing process to provide upon cooling a metallic bond between the components.

Lynch metals is the largest stocking distributor of aluminum brazing sheet in north america with locations in union nj and anaheim ca.

Sandwich panel is a structure made of many layers.

Navard is the only company in iran that is capable of manufacturing aluminium brazing sheet.

1075 lousons rd union nj 07083 p.

6951 clad brazing sheet 1100 3003 non heat treatable alloys castings.

Aluminium brazing sheet sheets is manufactured by roll bonding techniques to clad a core alloy ingot on one side or both sides with a low melting alsi alloy.

Being manufactured of aluminum alloys joined by brazing.

The clad sheet usually fig.

Aluminum brazing sheets for brazed automobile heat exchangers cladding an aluminum silicon alloy with a brazing sheet provides an aluminum alloy that has the thin walls necessary for use in automobile heat exchangers as well as such desirable characteristics as high strength corrosion resistance and formability.

This thin layer usually makes up 5 to 10 of the total thickness of the brazing sheet.